The Original Manufacturer Of LED lighting

RioTinto

RioTinto  2026-02-28

2026-02-28

The Most Environmentally Friendly Light Source in Human History

A Light Emitting Diode, or LED, is a type of new semiconductor-based solid-state light-emitting device that uses solid semiconductor chips as the luminous material.When a forward voltage is applied to the two ends, carriers in the semiconductor recombine, causing photon emission and thus producing light.

LEDs made from different materials emit light at different wavelengths, resulting in various colors.

LEDs are known for their low energy consumption, small size, long lifespan, non-polluting nature, fast response time, low driving voltage, strong resistance to vibrations, and high color purity. As a result, they are hailed as the next generation of lighting sources and green light sources.

Today, LEDs have become an integral part of modern life, appearing in every corner of our daily lives. Examples include status indicators on consumer electronics, household appliances, toys, and instruments; various road traffic signals; large flat-panel displays in airports and train stations; and ubiquitous giant advertising billboards.

In recent years, with continuous technological advancements, especially the development of blue light LEDs, white light LEDs have become feasible. This has led to the development of various LED lighting products with diverse functions and designs, giving white light LEDs an incredibly promising future in the field of lighting.

According to the brightness, LEDs can be divided into ordinary brightness LEDs and high brightness LEDs.

Among them, ordinary brightness LEDs are mainly made of materials such as GaP, GaAsP and AIGaAs, mainly including red, orange and yellow light products;

High brightness LEDs are mainly made of materials such as AIGaInP and GaN, mainly including red, orange, yellow, green, blue and white light products.

LEDs of different materials and brightness correspond to different application fields. In recent years, high brightness LEDs based on GaN and AIGaInP materials have gradually become the mainstream of LED industry development.

Chips, packaging, and applications form the foundation of the LED industry chain

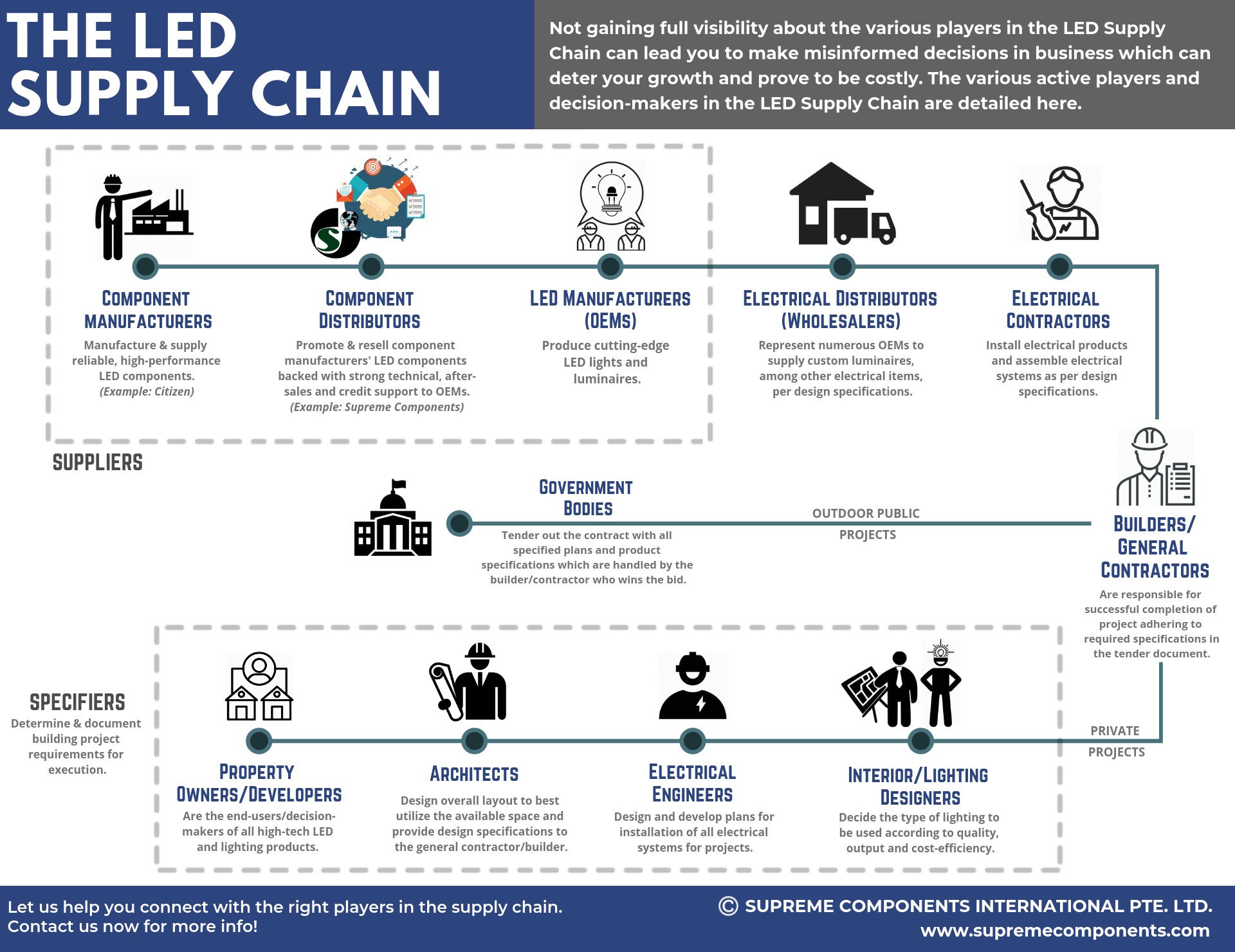

The LED industry chain includes five links: upstream substrate production, epitaxial wafer and chip manufacturing, midstream packaging, and downstream applications.

Among them, the LED epitaxial wafer and chip manufacturing link in the upstream of the industry chain is the key link of the entire industry chain.

LED substrate is the main raw material for producing LED epitaxial wafers. Currently, there are four main types of LED substrate materials, namely sapphire, SiC, Si and GaAs.

Among them, sapphire, SiC and Si are used to produce blue and green LEDs, and GaAs is used to produce red and yellow LEDs.

LED epitaxial growth refers to the process of forming a semiconductor light-emitting material film on an LED substrate using various epitaxial growth methods (such as LPE, MOCVD, MBE, etc.) to make LED epitaxial wafers.

This link is the link with the highest requirements for production equipment and technical processes in the LED production process. The quality of LED epitaxial wafers has an important impact on the quality of downstream products.

The current mainstream technology for producing high-brightness LED epitaxial wafers is MOCVD (metal organic chemical vapor deposition).

LED packaging refers to the link of connecting the external leads to the LED chip electrodes to form LED devices. The main function of packaging is to protect the LED chip and improve the light extraction efficiency.

The LED application link is to use LED devices to make LED application products for end users in response to various market demands, such as indicator lights, display screens, LCD backlights, LED lighting fixtures, etc. The technology in this link is mainly reflected in system integration, with a wide range of technologies and diverse characteristics.

The lighting market remains stable, while the direct display and backlight sectors are booming

LED downstream application areas are divided into three scenarios: lighting, display, and backlight. The demand in the lighting field has remained basically stable in recent years.

LED light sources have achieved a high penetration rate in the lighting field, while in the direct display and backlight fields, especially Mini/Micro LED is still in a booming stage.

LED lighting has the characteristics of high energy efficiency, high reliability, and high environmental protection, which makes it a global replacement for traditional lighting methods.

1. High energy efficiency: Compared with incandescent lamps, LED lamps only consume 1/5~1/8 of the energy to emit the same intensity of light, avoiding a large amount of energy being converted into heat energy instead of light energy.

2. High reliability: The service life of incandescent lamps is usually 1,000 hours, and the average life of LED lamps can reach 25,000 hours.

In addition, the service life of LED lamps is 8 times longer than that of halogen lamps and 2.5 times longer than that of fluorescent lamps. Long life saves replacement and maintenance costs.

3. High environmental protection: LED lamps do not contain harmful substances in mercury lamps, and are more environmentally friendly in production and recycling.

According to Trendforce statistics, LED lamps and lamps account for more than 70% of all lighting solutions in the world. LED has become the mainstream application product in the lighting market.

On the one hand, it benefits from its excellent performance. On the other hand, governments of various countries have issued relevant energy-saving and emission reduction policies, which greatly promotes the popularization of LED lamps.

In 2008, my country launched special funds from the central government to subsidize the promotion of energy-saving lamps and gradually eliminate incandescent lamps and other inefficient lamps in use.

In 2013, my country began to implement fiscal subsidies for the promotion of LED products, which greatly promoted the pace of transformation of domestic energy-saving lamp leading companies from traditional products to LED products.

The LED lighting market has ushered in a stage of vigorous development. According to Statista estimates, the global penetration rate of LED lighting is expected to reach 76% in 2025 and 87% in 2030.

Although the penetration rate brought by new installations has slowed down, secondary replacement LED lamps will play a more important role in demand from 2024.

Trendforce predicts that 5.788 billion LED lamps will come from secondary replacement demand this year, and the LED lighting market is expected to develop steadily in the next few years.

Global LED Penetration Rate and Forecast in Lighting Solutions

Global LED lighting new installation and replacement demand forecast (unit: million pieces)

From the perspective of quantity, the demand for secondary replacement may bring a new growth curve for LED lamp beads;

On the price side, LED lighting chips experienced a rapid decline before 2018. At the end of 2017, the price of LED lamp beads fell by 68% compared with the beginning of 2012.

The essence of the decline in LED lamp prices lies in technological progress. Manufacturers can use smaller LED chips to achieve the same brightness. Since 2010, the average annual rate of LED has increased by 6lm/W-8lm/W.

From the cost per unit lumen (brightness), the rate of chip price decline is similar to that of lamp beads. At the end of 2017, the LED cost per thousand lumens fell by 69% compared with the beginning of 2012.

In recent years, the price of LED lighting chips has not fluctuated much, and the output value of the entire market has fluctuated mainly with sales.

Trendforce predicts that the global lighting LED lamp bead market output value is expected to reach US$11.1 billion in 2026, with a compound growth rate of 8.4% from 2021 to 2026.